Tolerance – The acceptable error allowed when machining a dimension, or the total amount a dimension may vary.

All dimensions in a drawing have a tolerance.

Some dimensions require smaller tolerances than others.

Example: If the diameter is

Some dimensions require smaller tolerances than others.

Example: If the diameter is

ᴓ2.00inches ± 0.03, it needs to be machined between 1.97 and 2.03 inches.

Error -

Smaller allowable error = larger manufacturing cost

Error -

Smaller allowable error = larger manufacturing cost

Economics of Machining – 4 factors:

1. Machining Cost

labor + overhead, total time per piece.

increased speed = reduced cost

1. Machining Cost

labor + overhead, total time per piece.

increased speed = reduced cost

2. Material Cost

3. Tool Cost

increased speed = more costly tools

(tool life decreases with speed)

improved lubricants and coatings extend tool life

increased speed = more costly tools

(tool life decreases with speed)

improved lubricants and coatings extend tool life

4. Set-up costs

Accuracy - How close to a true value

Precision – how repeatable results are

Acceptable - Does the part serve it's function?

Interchangeable parts - what systems will it be used in?

3 Different forms to express tolerance:

Acceptable - Does the part serve it's function?

Interchangeable parts - what systems will it be used in?

3 Different forms to express tolerance:

A. Unilateral (asymmetrical) range of values that deviate in only one direction, +x, -y.

B. Bilateral (symmetric) equal deviations in the part ± x.

C. Limit - provide max and min values: Xmax/Xmin

Two types of tolerances: 1. Dimensional - accuracy in terms of size and dimensions

2. Geometric - accuracy in terms of shapes, locations, and profiles.

General tolerances:

Define acceptable level of error for all dimensions in a drawing that are not individually identified.

Typically in bilateral form

Found in title block, or added as a note to drawing.

Linear Tolerances:

Specific tolerance for a particular feature that is different than the general tolerance.

Matching or Mating Parts:

Components that are designed to fit to one another within a prescribed degree of accuracy.

4 parameters for mating parts:

4 parameters for mating parts:1. Tolerance of the first mating part

2. Tolerance of the second mating part

3. Allowance - maximum amount of interference (tightest fit) between two mating parts. Occurs when:

Hole - machined to smallest size

Shaft - machined to largest size

Allowance = Smallest possible Hole (SH) - Largest Possible shaft (LS)

4. Maximum clearance - Max space between two mating parts, or loosest fit.

Maximum clearance = Largest possible Hole (LH) - Smallest Possible Shaft (SS)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Example for a shaft and pulley:

Shaft

upper limit: ᴓ.4975

lower limit: ᴓ.4955

Shaft tolerance (ST) = 0.4975-0.4955 = 0.0020

.

Hole in pulley:

upper limit: ᴓ.5004

lower limit: ᴓ.5000

Hole tolerance (HT) is 0.5004-0.5000 = 0.0004.

Allowance = 0.5000 (SH) - 0.4975 (LS) = 0.0025

Maximum Clearance = 0.5004 (LH) - 0.4955 (SS) = 0.0049

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Calculations for Tolerance For mating parts:

.1. Basic-Hole:

diameter = minimum hole size = constant,

dimensions and tolerances calculated using min hole size.

convenient for manufacturing - easier to adjust the size of a shaft (grind it down) than to adjust the size of the hole.

Use min hole size - you can enlarge a hole, but if you drill it too large, you can't go back to make it smaller, so it's better to start out with it too small.

2. Basic-Shaft Systems

diameter = maximum shaft size

dimensions and tolerances calculated using max shaft size.

Used in textile industry, not as common as basic hole.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Fit: Degree of tightness between mating parts.

Do parts need to slide freely within an assembly?

Do parts need to be held tightly together?

3 Types of Fits

1. Clearance Fit - LC - designed to have room (clearance) between parts. Shaft is always smaller than the hole.

(The piston in combustion engine is a clearance fit)

2. Interference Fit - LN, FN - forced, or press fit:

Diameter of shaft larger than hole, mating parts interfere with one another, both parts elastically deform.

Shrink fitting: outside is heated (expands), inside is cooled (contracts)

3. Transition Fit - LT - Two parts can either clear or interfere with one another. Allowance is negative or zero, maximum clearance is positive.

line fit - allowance = 0.

Fits

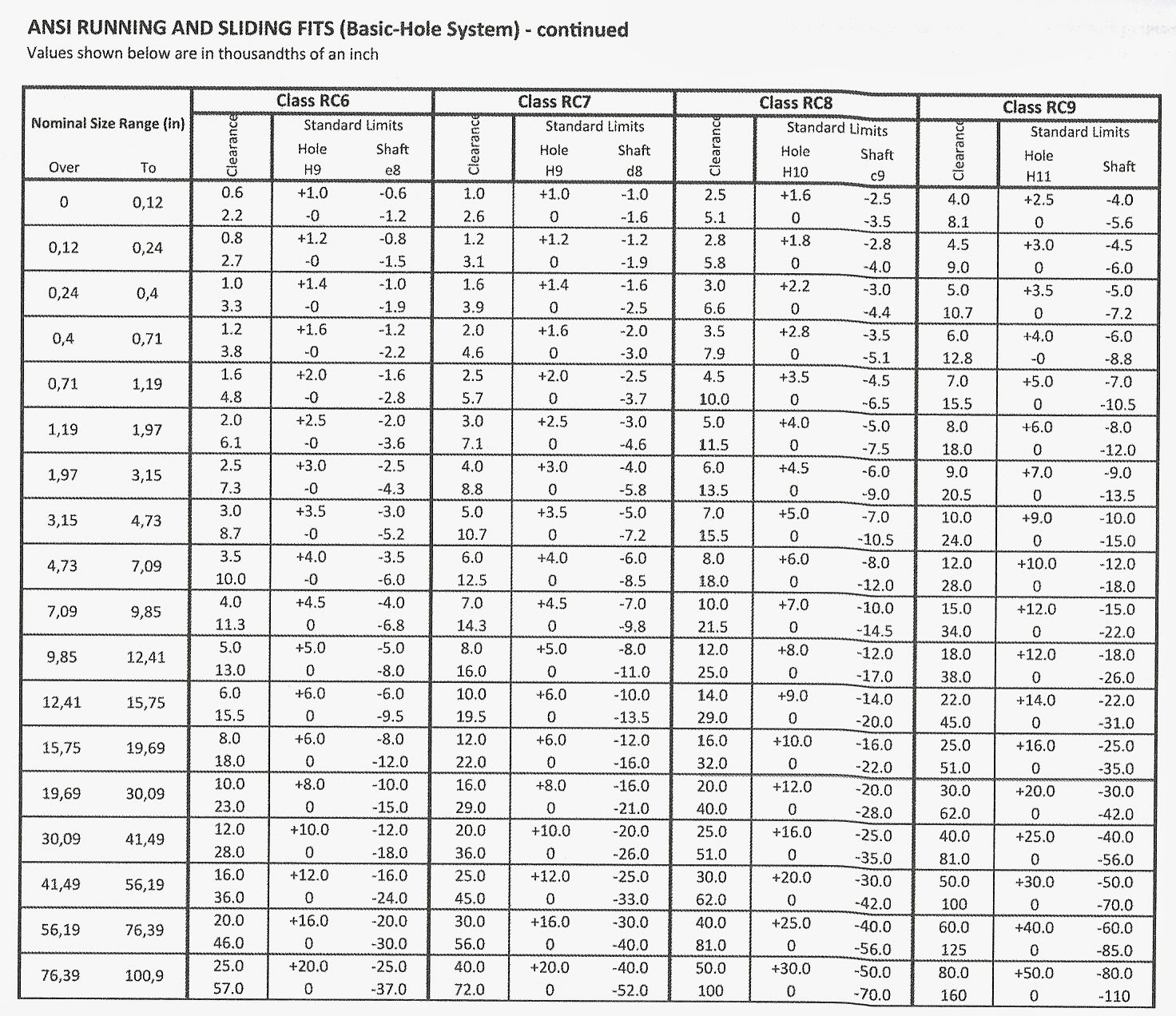

English Fits:

http://www.cobanengineering.com/Tolerances/ANSILimitsAndFits.asp

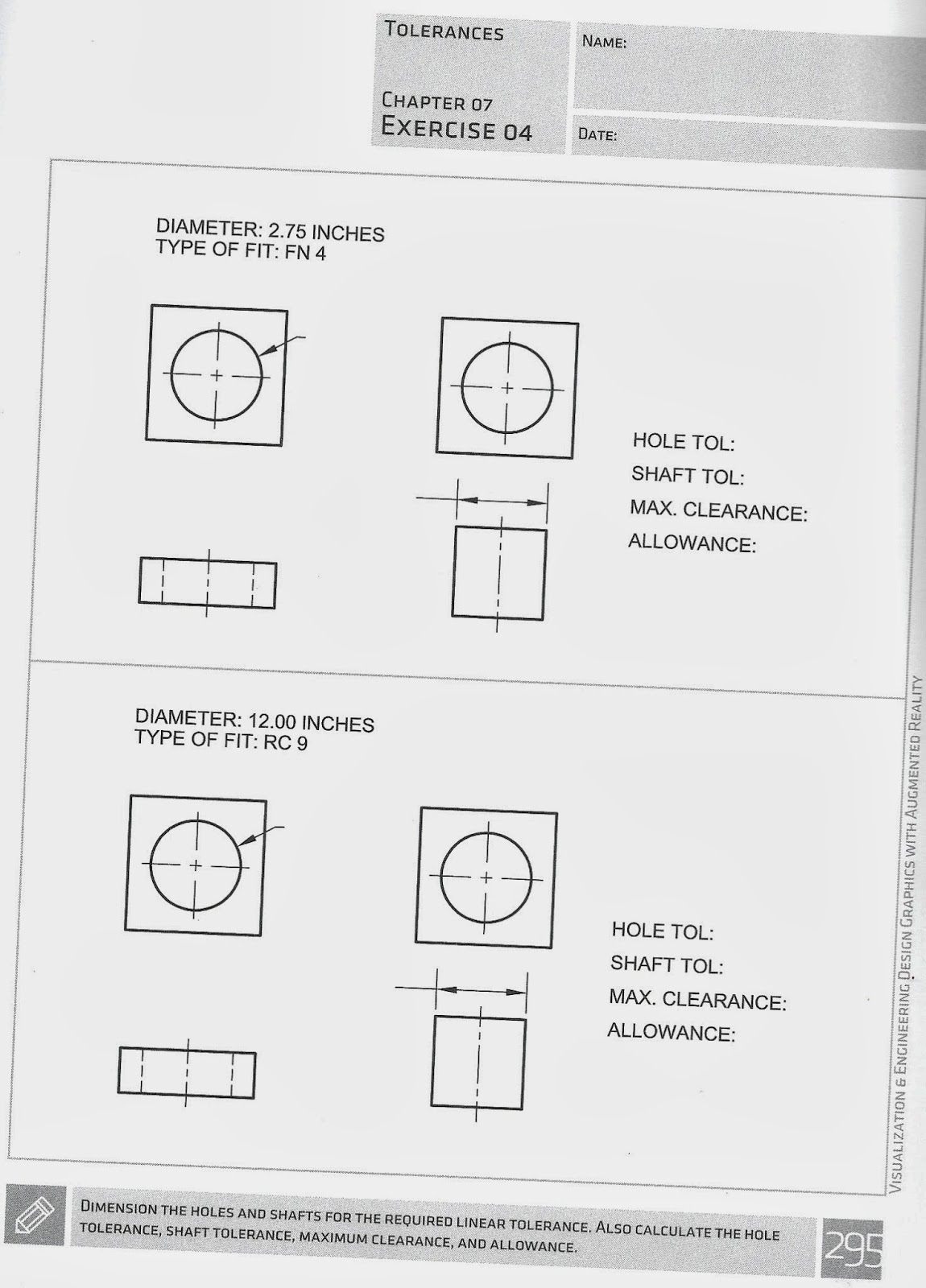

Fig 7.14 - example RC tolerance table

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Example pg 276:

Find the tolerances for an RC2 cylindrical fit ᴓ3.00 hole/shaft assembly:

Hole tolerance = +0.0007 and 0

Shaft tolerance: -0.0004 and -0.0009

Add or subtract tolerances from the base diameter

Largest Hole (LH) = 3.00+.0007 = 3.0007

Smallest Hole (SH) = 3.00+ 0 = 3.0000

Largest Shaft (LS) = 3.00-.0004 = 2.9996

Smallest Shaft (SS) = 3.00-0.0009 = 2.9991

.Hole Tolerance = 3.0007 - 3.000 = .0007

Shaft tolerance = 2.9996-2.9991 = 0.0005

Max Clearance = 3.0007 - 2.9991 = 0.0016

Allowance = 3.0000 - 2.9996 = 0.0004

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Metric Fits - 278

Complete Fit:

Two tolerance grades

1. Hole Tolerance

2. Shaft tolerance

Nomenclature example:

20H7/g6

20 = diameter in mm

H7 = hole tolerance

H = deviation

7 = IT grade

g6 = shaft tolerance

g = deviation

6 = IT grade

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Example: Find a H7/s6 (Medium drive) cylindrical fit for a 10mm diameter hole/shaft assembly:

g6 = shaft tolerance

g = deviation

6 = IT grade

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Example: Find a H7/s6 (Medium drive) cylindrical fit for a 10mm diameter hole/shaft assembly:

10H7/s6

Largest hole = 10.015

Smallest Hole = 10.00

Largest Shaft = 10.032

Smallest Shaft = 10.023

Hole Tolerance = 10.15-10 = 0.015

Shaft tolerance = 10.032-10.023 = 0.0009

Max clearance = 10.015-10.023 = -.008

Allowance (Min clearance) = 10-10.032 = -0.032

Max clearance = 10.015-10.023 = -.008

Allowance (Min clearance) = 10-10.032 = -0.032

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

Geometric Tolerances

Error in shape, form, location, and orientation.

Symbols for geometric tolerance:

Label in control frame:

Type of tolerance (// - make two sides parallel to one another)

Tolerance Value (0.15)

Reference point (A - the sides that are supposed to be parallel)

MMC - Maximum Material Condition

LMC - Least Material Condition

Manufacturing - Use large or small end of tolerance ranges to increase strength / decrease weight / etc.

,

Tolerances of Form:

Flatness & Roundness

Straightness &

Cylindricity: Combo of roundness and straightness

Profile Tolerance:

Error in arcs, curves, and irregular profiles.

Tolerance of profile & Orientation:

Parallelism & Perpendicularity

Position:

Concentricity:

Symmetry:

Runouts:Part revolved around axis

Set up an Excel spreadsheet, copy it for all the problems, so all you have to do is look up the #'s in the tables, and type them in.

Here's the first one:

Metric

Just do #1 and #2

: